Exploring gasoline oxidation chemistry in jet stirred reactors

Exploring gasoline oxidation chemistry in jet stirred reactors

B. Chena, Z. Wanga, J.-Y. Wanga, H. Wang, C. Togbé, P.E. Álvarez Alonsoa, M. Almalki, M. Mehl, W.J. Pitz, S.W. Wagnon, K. Zhang, G. Kukkadapu, P. Dagaut, S. Mani Sarathy

Fuel, 236, pp. 1282-1292, (2019)

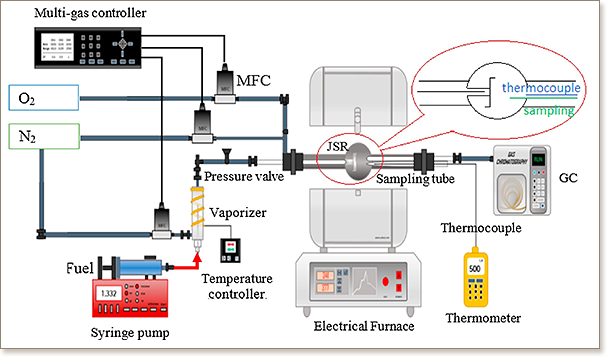

Recent decades have seen increasingly restrictive regulations applied to gasoline engines. Gasoline combustion chemistry must be investigated to achieve a better understanding and control of internal combustion engine efficiency and emissions. In this work, several gasoline fuels, namely the FACE (Fuel for Advanced Combustion Engines) gasolines, were selected as targets for oxidation study in jet-stirred reactors (JSR). The study is facilitated by formulating various gasoline surrogate mixtures with known hydrocarbon compositions to represent the real gasolines. Surrogates included binary mixtures of n-heptane and iso-octane, as well as more complex multi-component mixtures. The oxidation characteristics of FACE gasolines and their surrogates were experimentally examined in JSR-1 and numerically simulated under the following conditions: pressure 1 bar, temperature 500–1050 K, residence time 1.0 and 2.0 s, and two equivalence ratios (ϕ = 0.5 and 1.0). In the high temperature region, all real fuels and surrogates showed similar oxidation behavior, but in the low temperature region, a fuel’s octane number and composition had a significant effect on its JSR oxidation characteristics. Low octane number fuels displayed more low temperature reactivity, while fuels with similar octane number but a larger number of n-alkane components were more reactive. A gasoline surrogate kinetic model was examined with FACE gasoline experiments either measured in JSR-2, or taken from previous work under the following conditions: pressure 10 bar, temperature 530–1200 K, residence time 0.7 s, and three equivalence ratios (ϕ = 0.5, 1.0 and 2.0). Comparison between FACE gasoline experimental results with surrogate model predictions showed good agreement, demonstrating considerable potential for surrogate fuel kinetic modeling in engine simulations.

"KAUST shall be a beacon for peace, hope and reconciliation, and shall serve the people of the Kingdom and the world."

King Abdullah bin Abdulaziz Al Saud, 1924 – 2015

Thuwal 23955-6900, Kingdom of Saudi Arabia

© King Abdullah University of Science and Technology. All rights reserved