Current Research

The CPC group is concerned with the systematic development of kinetic mechanisms for different hydrocarbons. The mechanisms include both low and high temperature reaction classes with rate coefficients either adopted from literature or calculated using computational methods. The models are validated against experimental ignition delay data from shock tubes and rapid compression machines or speciation data from jet stirred reactors. We have international collaborations with top researchers specializing in this field, specifically Dr. Charles K. Westbrook, Dr. William J. Pitz and Dr. Marco Mehl at Lawrence Livermore National Laboratory and Prof. Henry Curran at the National University of Ireland in Galway, which ensures the development of state of the art combustion models.

In a single overall step, combustion is the reaction of the fuel with molecular oxygen to produce carbon dioxide, water and most importantly heat. However, this naturally never happens in a single step, but rather in a series of elementary reactions that

constitute “the reaction mechanism”. The increasing demand for high energy and low emission fuels necessitates the investigation of the detailed oxidation chemistry and kinetics of potential fuel molecules (pure component or mixtures)

at the fundamental level. The mechanisms are required to accurately predict the ignition behavior and emission profiles of the fuels they represent over a wide range of conditions that are applicable to different types of engines. A better understanding

of the fuel auto-ignition chemistry is vital for the development of cleaner and more efficient engines such as the homogeneous charge compression ignition engine (HCCI).

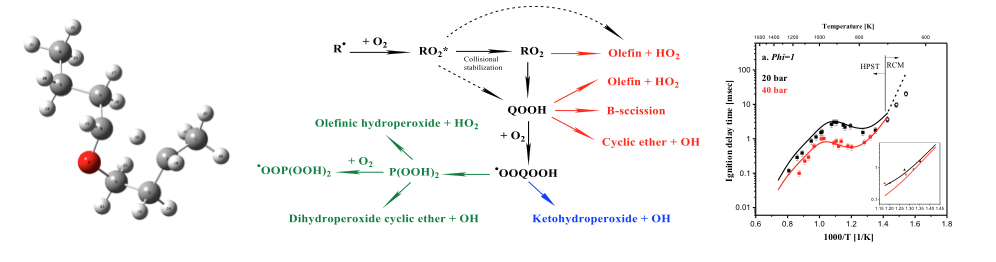

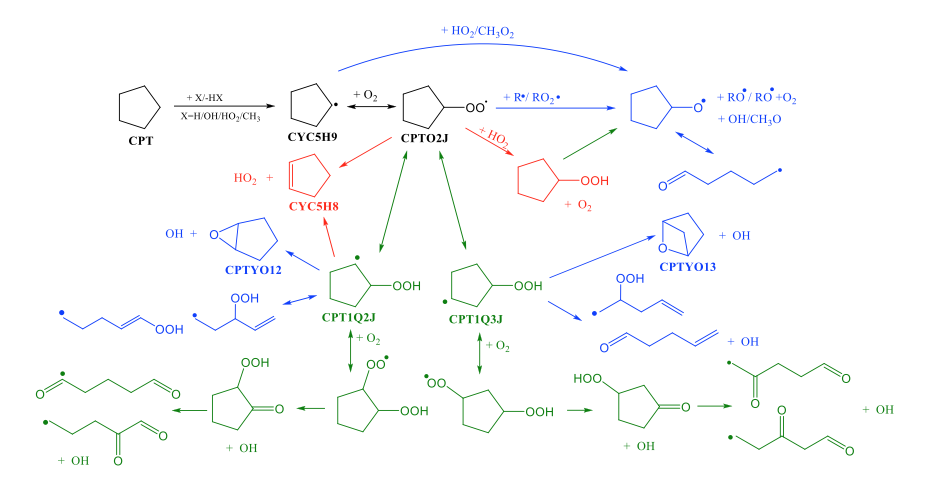

Generally, a detailed mechanism will include both the low and high temperature

schemes. The unimolecular decomposition of the fuel and the alky radicals in addition to isomerization reactions are important at high temperatures. Meanwhile, at low temperatures, fuel radicals add O2 to produce the peroxy radicals (ROO) that undergo

chain branching and chain propagation reactions leading to negative temperature coefficient (NTC) behavior. In addition to the conventional pathways, new reactions are being added to the developed mechanisms based on recent experimental findings.

For example, recently published papers [1, 2] from our group provide evidence for the presence of a third molecular oxygen addition step in the low temperature oxidation scheme.

In addition to the mechanism which includes all the elementary steps,

the thermodynamic and transport properties of different species are needed to predict ignition. The thermodynamic properties are calculated using the group additivity method developed by Benson et al. [3] and implemented in THERM software [4]; whereas,

transport properties are obtained using various empirical correlations.

The ignition properties of a fuel are highly sensitive to its combustion chemistry and the rates of a few elementary reactions. Therefore, in order to accurately predict

these properties, precise knowledge of reaction kinetics is required. In our team, this is accomplished through the use of computational methods and specialized software.

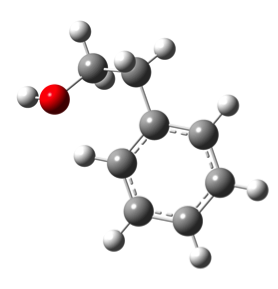

We use high-level electronic structure calculations to scan for the minimum energy conformers of reactants, products and transition states. This is followed by geometry optimization and frequency calculations that are carried out using Density Functional

Theory methods such as M06-2X and B3LYP, implemented in Gaussian 09 [5] software. Single point energy calculations are realized using MOLPRO software and coupled cluster theory. The calculated values and Transition State Theory are then used to determine

the rate constants of the reaction. These are fitted to the modified Arrhenius equation resulting in three temperature-independent coefficients. In order to ensure the accuracy of the calculated rate constants, we account for the hindered rotor potential

and asymmetric Eckhart tunneling factor. We also evaluate the pressure-dependency of certain reactions using RRKM-based master equation analysis and collision theory.

For computational studies we collaborate with well-known researchers in the

field, such as Dr. Alexander Davis of Franklin and Marshall College[6], Dr. Abhijeet Raj of the Petroleum Institute [7] and Dr. Judit Zádor of Sandia National Laboratories[8].

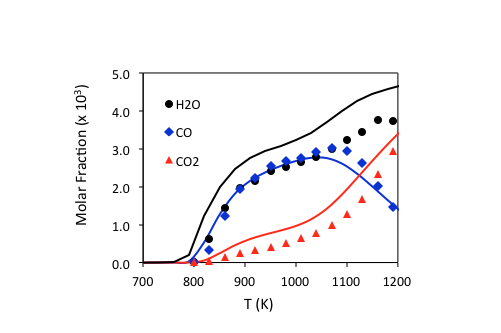

The developed chemical kinetic model is coupled with a physical model to simulate a specific combustion application with a specific geometry and operating conditions. The simulations serve to validate the models against experimental data and ensure their predictive capabilities over a wide range of conditions. They are accomplished using a numerical solver that evaluates the chemical kinetic, thermodynamic, and transport properties of each differential element as time proceeds. In our group, we commonly use Reaction Design’s CHEMKIN suite [9] of program for simulating chemically reacting flow systems. Other commonly used programs include CANTERA [10, 11] and OPENSMOKE [12, 13]. These models can also be run through CloudFlame, a specialized website developed by our colleagues at CPC. The CHEMKIN suite is used to simulate a variety of combustion systems including shock tubes, premixed flames, diffusion flames, and partially and perfectly stirred reactors where properties like ignition delay time, speciation, flame speeds…etc can be obtained.

"KAUST shall be a beacon for peace, hope and reconciliation, and shall serve the people of the Kingdom and the world."

King Abdullah bin Abdulaziz Al Saud, 1924 – 2015

Thuwal 23955-6900, Kingdom of Saudi Arabia

© King Abdullah University of Science and Technology. All rights reserved